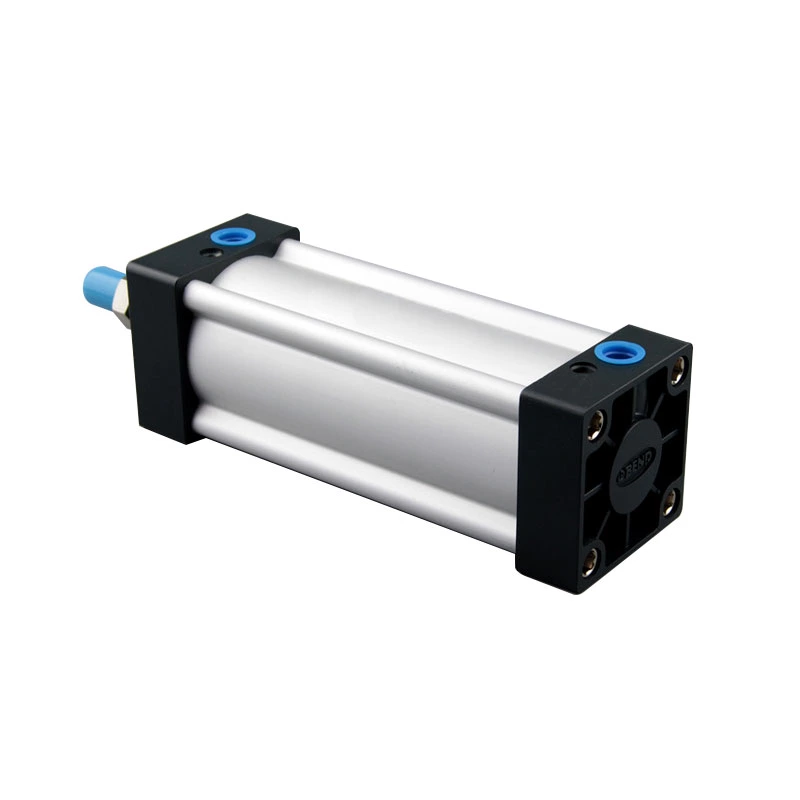

During magnetic piston air cylinder installation, attention shall be paid to that the flange installation, its force and support center are on the same axis, and the connection between the flange and the support base shall make the flange face bear the force, rather than the fixed Gong nail bear the tension. Cylinder piston rod is not allowed to bear eccentric load or transverse load. Extra long stroke cylinder should be supported or guided. Before the cylinder is connected to the pipeline, the dirt in the pipeline shall be clear. Prevent sundries and dust from entering the cylinder cavity. If necessary, the buffer wire core can be adjusted to adjust the buffer effect so as to avoid collision between the piston and the cylinder head and damage the parts. During use, the fasteners shall be checked frequently to prevent loosening. The diameter of the air inlet and exhaust pipe joint of the cylinder is generally compatible with the cylinder diameter of the cylinder. According to the use situation, the user installs a one-way throttle valve in the air inlet and exhaust pipe to adjust the piston rod of the cylinder.

Products

- Sensor

-

- Inductive proximity switch

- Capacitive Proximity Sensor

- Ultrasonic Sensor

- Photoelectric Sensor

- Mirror Reflector

- Safety Light Curtains

- Color Mark Sensor

- Fiber Optic Amplifier

- Sensor connector

- HOKUYO Sensor

- Autonics Sensor

- Hall sensor

- Load cell sensor

- Magnetostrictive Position Sensors

- Temperature Sensor

- Rotary Encoder

- Programmable Logic Controller (PLC)

- HMI and Text Panel

- Pneumatic Products

- Slip ring

- New Energy System

- Switch

- Cable Gland

- Fuse

- Socket

- Solid State Relay (SSR)

- Counter

- Switching power supply

- Terminal Blocks

- Warning light

- Pump

- Metal Push Button

- Temperature Controller

- Contactor

- Voltage Meter

- Other Products

- Pneumatic Fittings

- Air Cylinder

- Pneumatic Valve

- Air Tube

- Pneumatic Dust Gun

- Air Source Treatment

- FESTO Pneumatic